Fire Alarm

ADRESSABLE FIRE ALARM EXPLAINED

An addressable fire alarm system is made up of a series of fire detectors and devices that are connected back to a central control panel.

With addressable systems, each device has an address or location, enabling the exact detector that was triggered to be quickly identified. This makes addressable alarm systems ideal for large buildings, particularly commercial premises spread over a wide area.

Advantages of addressable fire alarms

* Quickly determine the location of a fire.

* Specific actions can be programmed by the user.

* Reduced likelihood and better handling of false alarms.

* More reliability, less likely to lose connection.

* Lower overall cost of wiring.

* Ability to monitor integrity of the system, with detector health checks.

Fire alarm systems that can be programmed

One of the biggest advantages of addressable fire alarm systems is that they can be configured so that a specific action triggers a specific response.

For example, cause and effect programming can be used to say that a particular ‘cause’ such as activation of a fire detector, has the effect of alarms sounding in a specified area and the system being put on alert mode in another. This means that phased evacuation can take place, with priority areas evacuated first. Each area of a building can then be evacuated one at a time, which allows safer fire evacuation procedures in large buildings.

Reduce false fire alarms

False alarms cause disruption and can be costly, so it’s in any business’s interests to minimise their impact and reduce the likeliness of them occurring in the first place.

One of the advantages of addressable fire alarms is that they can allow air to be monitored through the detectors, so if air is contaminated for example with dust (which can activate some fire alarm systems) then a ‘pre-fire’ warning is triggered. This allows investigation to take place, so any issues can be rectified before a full scale false activation of the system takes place.

Addressable fire alarms are more reliable than conventional

Due to the way that addressable alarm systems are connected, any breaks in the circuit caused by damage are less likely to result in devices being disconnected. Unlike conventional systems, all devices are wired up on a loop and are connected to the panel unit at both ends. Therefore if connection breaks at one end, devices will still be connected.

Cost of wiring up alarm system is cheaper

Addressable fire alarms are wired on a loop, which is basically a circuit that connects the system to other devices such as sprinkler systems, call points and detectors.

Monitoring and checking all individual fire detectors for faults

Fire alarms are arguably one of the most critical aspects of fire safety on your premises. Another benefit of addressable fire alarm systems is that all devices can be individually monitored and checked for faults, which makes maintenance easier. If an issue is found with a particular detector for example, then a notification will be received by the central control panel.

Having an addressable system therefore means that any problems can be discovered immediately so that they can be rectified, ensuring that everything is in good working order should an incident occur.

Do you need an addressable fire alarm?

This will depend on the requirements of your premises. Usually addressable fire alarms are more suited to larger commercial premises, as they provide accurate and detailed information as to the location of a fire, which isn’t necessary in smaller buildings.

These systems provide sophisticated fire protection, so therefore they do tend to be more expensive than conventional alarms overall. However if having a reliable method of alerting you to danger, that cuts down false alarms and allows for smooth evacuation is critical to your business, then it’s a worthwhile investment.

Of course, the type of fire alarm system installed is important to get right and we’d strongly advise talking to a fire protection expert before making a decision.

WIDE RANGE OF PANEL FROM 2 LOOP UP TO 8 LOOP (each loop can accommodate up to 125 devices each)

ARITECH ADRESSABLE PANEL CAN BE NETWORKED TO ONE GLOBAL REAPETER (in case of large complex with more than one building in the complex)

ARITECH ADRESSABLE PANEL ARE ALSO IP ENABLE FOR REMOTE CONTROL AND VIEWING FROM A CENTRAL CONTROL Rm.

OUR ARITECH PANEL CAN BE INTERFACED WITH OUR TRUVISION CCTV ET TRUPORTAL ACCESS CONTROL

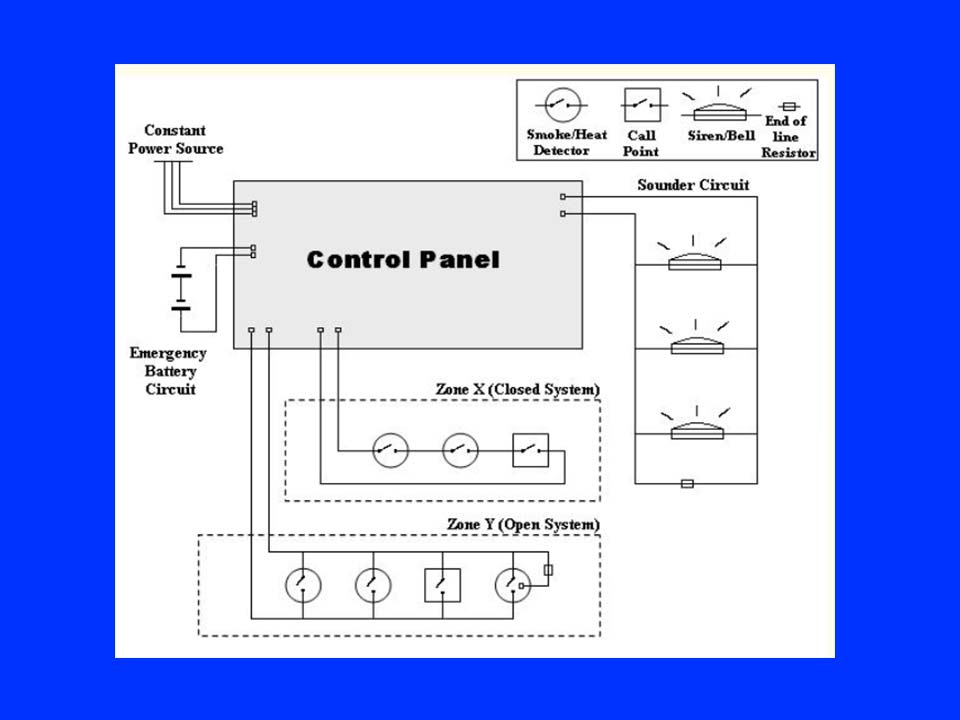

Conventional Fire Alarm Operation Explained

What is meant by the term “Conventional Fire Alarm System”?

When referring to fire alarm systems, you will most likely hear the term “a conventional system”. If you do not work within the fire industry, you may not understand what is meant, by the term conventional.

A conventional system is a fire alarm that identifies the activated detector or manual call point by a zone LED on the fire alarm panel.

When a devices is activated it automatically trigger ALL the alarm bell connected to the panel.

The alarm bell can also be activated (Evacuation) manually from the panel.

To cancel a Fire alarm two action are required:

1) Silence panel

· The user would have to search the zone/area to either locate the activated device or the fire. This would increase the “seek and search” time and especially if there are many devices on the system.

2) Reset panel (after investigation to the origin of alarm).

Conventional Systems are very basic as the information produced by the fire alarm control panel are only audio visual by the mean LED (Light Emitting Diode) and buzzer to indicate the status of the field devices and general information of the panel.

This is the reason we would advise that conventional systems should not be used in large buildings or systems with lots of devices or devices that may not be accessible

ARITECH FIRE ALARM PANEL 2 / 4 AND 8 ZONE ARITECH FIELD DEVICES

DECECTOR BASE / OPTICAL “SMOKE” DECECTOR / HEAT DECECTOR

MANUAL CALL POINT (WITH TEST KEY)

FIRE ALARM / ELECTRONIC SOUNDER / SOUNDER & BEACON

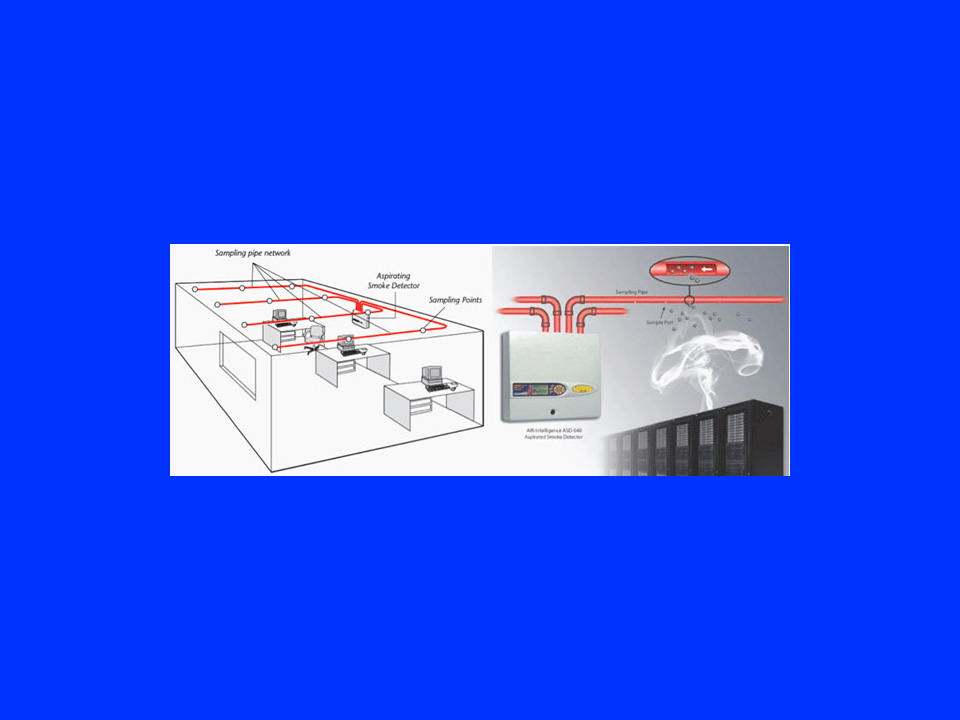

WHAT IS AN ASPIRATING FIRE ALARM SYSTEM?

An aspirating smoke detector (ASD) is a system used in active fire protection, consisting of a central detection unit which draws air through a network of pipes to detect smoke.

ASD are extremely efficient and very sensitive to the smallest smoke particle and used in area with a concentration of costly equipment susceptible to fire such as server Rm technical Rm

How does it work? An aspirating smoke detector (ASD) is a system used in active fire protection, consisting of a central detection unit which draws air through a network of pipes to detect smoke.[1] The sampling chamber is based on a nephelometer that detects the presence of smoke particles suspended in air by detecting the light scattered by them in the chamber. ASDs can typically detect smoke before it is visible to the naked eye.

In most cases aspirating smoke detectors require a fan unit to draw in a sample of air from the protected area through its network of pipes.

History In 1970 the Australian Commonwealth Scientific and Industrial Research Organisation (CSIRO) used a nephelometer to carry out research into forest fires. Subsequently, the Australian Postmaster-General’s Department engaged the CSIRO to investigate technologies that could prevent service interruption due to fire. After selecting a sample site to carry out research, the CSIRO suggested that the nephelometer should be used as the benchmark for the APO fire tests. This was installed to monitor smoke levels within the return-air ducts of the mechanical ventilation system, utilising a chart-recorder output display.[3]

At the conclusion of several weeks of testing, it was discovered that there no commercially available fire detection technology suitable for preventing damage to telephone equipment. One technology that did show great promise however was the nephelometer itself.[4]

In 1979, Xtralis, then IEI Pty Ltd., produced and sold an air sampling device they called VESDA (Very Early Smoke Detection Apparatus). The company redesigned the detector in 1982 to provide the reliability, features, size and reduced cost for export markets. ASD systems have gained popularity due to their ability to sense smoke long before a catastrophic incident.[5]

Design

ASD design corrects shortcomings of conventional smoke detectors by using a sampling pipe with multiple holes. The air samples are captured and filtered, removing any contaminants or dust to avoid false alarms and then processed by a centralized, highly sensitive laser detection unit. If smoke is detected, the systems alarm is triggered, and signals are then processed through centralized monitoring stations within a few seconds.

Unlike passive smoke detection systems, including spot detectors, ASD systems actively draw smoke to the detector through bore holes within a piping system that runs throughout the protected area. Furthermore, ASD systems incorporate integrity monitoring to ensure an alert is raised at any time the ASD’s ability to detect smoke is compromised. This is not the case with passive devices that are generally only electrically monitored with no ability to determine if smoke can actually reach the detection element.

ASD systems incorporate more than one level of alarm. This allows an ASD system to provide very early warning of an event, prompting investigation at the earliest smouldering stage of a fire when it is easily addressed. Other alarm levels may be configured to provide fire alarm inputs to fire systems as well as releasing suppression systems. ASD alarm sensitivities are configurable

and can be programmed to levels ranging from thousands of times more sensitive than a conventional detector, to much less sensitive. The detectors work best in non-volatile environments They can also be used in computer cabinets to alert users to the overheating of computer cables or individual computer components.

Installation and placement

An example of how a simple ASD unit with a single pipe could cover a five-room area

ASDs are suitable for environments where a highly sensitive rapid smoke detection capability is required. This makes them suitable in clean rooms; areas which contain goods easily damaged by fire, such as tobacco, electronic rooms and highly flammable liquid and gases. Often, normal point detectors will recognise the danger too late, as smoke often does not reach the ceiling quick enough for a fire to be detected in a timely fashion.[11]

As they can be easily hidden, pipe networks are suitable in environments where point detectors can be considered aesthetically displeasing, such as offices, apartments and hotel rooms. This factor also makes them suitable in locations where point detectors can be easily tampered with, such as in correctional facilities.[12]

Despite their high sensitivity ASDs can be used in dusty or dirty environments as long as correct design, installation and maintenance processes are followed. Most ASD products can accommodate a broad range of environments and applications – from both confined and open spaces to the cleanest or dirtiest environment, including telecomm, control rooms, waste treatment, mining and more.

INTELLINGENT FIRE ALARM PANEL

Intelligent fire alarm panel is a step ahead of the addressable panel specially designed for high security level environment such as large factory mining industry 5 stars hotel airports etc.

Why intelligent? Based on the same wiring principle than the addressable system, the devices are communicating at all time with all other devices connected to the panel and not only to the panel to ensure a maximum redundancy in case of component failure in the panel

Global leader in fire alarm, mass notification and hazard warning.

Whether Edwards™ detection and alarm solutions are protecting the lives and livelihoods of the people who make businesses run, or who receive treatment at healthcare institutions; whether they’re charged with protecting students, staff and faculty at the world’s finest universities, or preserving irreplaceable artifacts that bring humankind’s history to life; Edwards finds innovative ways to meet site-specific challenges and make every project a success.

Edwards’ solutions are modular, scalable, and meet the needs of applications ranging from fire detection to industrial signalling and mass notification – all technologically advanced innovations that deliver value and reliability for the entire service life of the product.

When facility owners and designers do business with Edwards, their investment is underwritten by a history of excellence and ingenuity that dates back over 140 years.

What is a CO DETECTION?

A carbon monoxide detector or CO detector is a device that detects the presence of the carbon monoxide (CO) gas in order to prevent carbon monoxide poisoning. In the late 1990s Underwriters Laboratories changed their definition of a single station CO detector with a sound device in it to a carbon monoxide (CO) alarm. This applies to all CO safety alarms that meet UL 2034 standard however for passive indicators and system devices that meet UL 2075, UL refers to these as carbon monoxide detectors.

CO is a colourless, tasteless and odourless compound produced by incomplete combustion of carbon-containing materials. It is often referred to as the “silent killer” because it is virtually undetectable by humans without using detection technology and, in a study by Underwriters Laboratories, “Sixty percent of Americans could not identify any potential signs of a CO leak in the home Elevated levels of CO can be dangerous to humans depending on the amount present and length of exposure. Smaller concentrations can be harmful over longer periods of time while increasing concentrations require diminishing exposure times to be harmful.[3]

CO detectors are designed to measure CO levels over time and sound an alarm before dangerous levels of CO accumulate in an environment, giving people adequate warning to safely ventilate the area or evacuate. Some system-connected detectors also alert a monitoring service that can dispatch emergency services if necessary.

While CO detectors do not serve as smoke detectors and vice versa, dual smoke/CO detectors are also sold. Smoke detectors detect the smoke generated by flaming or smouldering fires, whereas CO detectors detect and warn people about dangerous CO build-up caused, for example, by a malfunctioning fuel-burning device. In the home, some common sources of CO include open flames, space heaters, water heaters, blocked chimneys or running a car or grill inside a garage

Signs and symptoms of carbon monoxide poisoning may include:

* Dull headache.

* Weakness.

* Dizziness.

* Nausea or vomiting.

* Shortness of breath.

* Confusion.

* Blurred vision.

* Loss of consciousness.

Our KM 301 CO detection panel

The KM301 is a 1 Zone Carbon Monoxide (CO) detection control panel designed for applications where concentrations of CO may accumulate and needs to be controlled in order to protect lives. The panel is able to accommodate 1 supervised detection zone using KM170 or KMD300 CO detectors. The panel is compliant with UNE 23-301-88, CE, WEEE and RoHS.

* Elegant design

* 1 Supervised CO detection zone

* Easy to install and to use

* Language customisation using language inserts

* Clear and accurate display of CO levels per zone

* Up to 15 detectors per zone

* Fast response times

* Extraction and alarm outputs per zone

* Supervision of all CO detectors and zones

* Using surface mount technology with low current consumption

* Compatible with KM170 and KMD300 CO detectors

* UNE 23300:1984, CE, WEEE and RoHS compliant

* External and internal power supply support

WHAT is ATEX

WE have a wide range of ATEX as well as intrinsically safe fire alarm devices designed for special application and risk level area, please contact us for a survey

Technical definitions

In DSEAR, an explosive atmosphere is defined as a mixture of dangerous substances with air, under atmospheric conditions, in the form of gases, vapours, mist or dust in which, after ignition has occurred, combustion spreads to the entire unburned mixture.

Atmospheric conditions are commonly referred to as ambient temperatures and pressures. That is to say temperatures of −20 °C to 40 °C and pressures of 0.8 to 1.1 bar.[2]

Zone classification

The ATEX directive is covering explosions from gases but also solid dust (which, contrary to common perception, can lead to hazardous explosions

Hazard – Gas / vapour / mist

Zone 0 – A place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist is present continuously or for long periods or frequently

Zone 1 – A place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally.

Zone 2 – A place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Hazard – Powder / dust

Zone 20 – A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously, or for long periods or frequently.

Zone 21 – A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally.

Zone 22 – A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Effective ignition source

Effective ignition source is a term defined in the European ATEX directive as an event which, in combination with sufficient oxygen and fuel in gas, mist, vapour or dust form, can cause an explosion. Methane, hydrogen or coal dust are examples of possible fuels.[4]

Effective ignition sources are:

* Lightning strikes.

* Open flames. This varies from a lit cigarette to welding activity.

* Mechanically generated impact sparks. For example, a hammer blow on a rusty steel surface compared to a hammer blow on a flint stone. The speed and impact angle (between surface and hammer) are important; a 90 degree blow on a surface is relatively harmless.

* Mechanically generated friction sparks. The combination of materials and speed determine the effectiveness of the ignition source. For example, 4.5 m/s steel-steel friction with a force greater than 2 kN is an effective ignition source. The combination of aluminium and rust is also notoriously dangerous. More than one red hot spark is often necessary in order to have an effective ignition source.

* Electric sparks. For example, a bad electrical connection or a faulty pressure transmitter. The electric energy content of the spark determines the effectiveness of the ignition source.

* High surface temperature. This can be the result of milling, grinding, rubbing, mechanical friction in a stuffing box or bearing, or a hot liquid pumped into a vessel. For example, the tip of a lathe cutting tool can easily be 600 Celsius (1100 °F); a high pressure steam pipe may be above the auto ignition temperature of some fuel/air mixtures.

* Electrostatic discharge. Static electricity can be generated by air sliding over a wing, or a non-conductive liquid flowing through a filter screen.

* Radiation.

* Adiabatic compression. Air is pumped into a vessel and the vessel surface heats up.

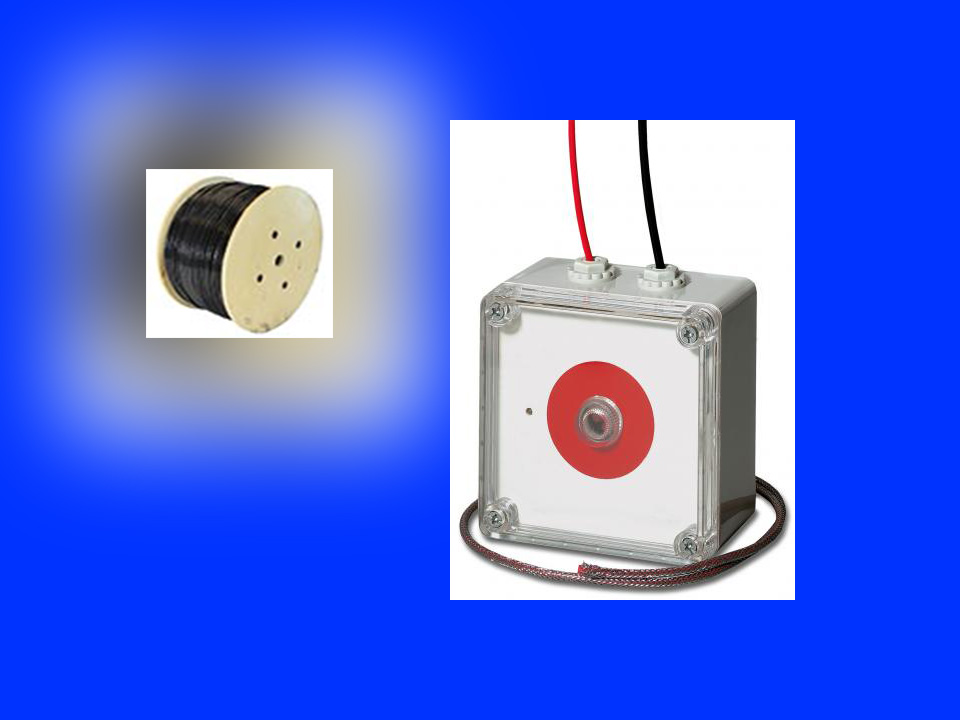

What is LHD DETECTION?

Linear Heat Detection (LHD) (also known as Linear Detection Wire or Linear Heat Detection Cable or Linear Heat) is a very commonly used method of fire detection. It can detect a fire anywhere along the length of the cable, and can be of lengths in excess of a kilometre.

Operation

Linear Heat Detection (LHD) cable is essentially a two-core cable terminated by an end-of-line resistor (resistance varies with application). The two cores are separated by a polymer plastic, that is designed to melt at a specific temperature (commonly 68 °C for building applications, and without which causes the two cores to short. This can be seen as a change in resistance in the wire.

There are a limited states the LHD cable can be in:

1. Open-circuit – Effectively an infinite resistance

2. Normal Operating Condition – Apparent resistance will be the same as the end-of-line resistor

3. Fire Detection – Resistance of the Linear Heat Cable to the short circuit

LHD CONTROLLER WIDE RANGE OF LHD CABLE AVIALBLE

Our partner suppliers.